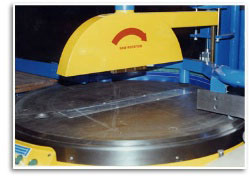

Computerised Rotary Saw

Product Description

The CRS is a compact fully computerised saw ideal for use in truss plants where space is at a premium. It is capable of high volume production, cutting both large and small quantities efficiently. Alternatively, it can be used for short run production sawing, leaving component cutters free for the longer runs for which they are designed. It is simple to use, so novice sawyers can quickly become productive.

Computer details

Pentium (minimum), Windows 95, Network card (BNC/UTP combination.

Requirements

- Power: 415V, 3-phase & neutral, 20A

- Compressed air: 690kPa, 100psi

Saw details

- Saw blade:

- 540mm diameter

- 30mm bore

- 4mm thick

- 72 teeth

- specially machined

- Saw motor – 4kW.

- Number of blades – 1.

Product Features

- Incorporating the unique sequence cutting which reduces cutting strokes by up to 30% and minimises wastage.

- Optional ink jet marking system.

- Simple and rugged construction.

- Will cut very short members.

- The operator can at any time override the program to recut or optimise cutting sequence procedure.

- Manual input of members can be made at any time.

- The operator can easily scroll forward or back to select members.

- Data can be down loaded by LAN or floppy disk.

Cutting Details

- Range of working angulation – 7.8° to 172.2°. Saw can angulate to 0° at any offset.

- Maximum offset – 95mm.

- Minimum offset – 0mm.

- Maximum timber length – 6000mm.

- Minimum timber length – 30mm.

- Maximum working timber width – 190mm.

- Will cut width of 490mm at 90°.

- Minimum timber width – 40mm.

- Maximum timber thickness – 115mm.

- Setup time - operator simply selects a member with an arrow key and presses enter.

- Output – 80-90 pieces per hour with one operator, (operator dependent).

Cutting limits: Timber SizeAngleOffset 70 x 359º35mm90 x 3510.7º45mm120 x 3515º60mm140 x 3517º70mm190 x 3523º95mm

Details: Configuration (left or right hand) – Left hand as follows. Wooden in-feed bench on steel frame, with moving timber pusher mounted to left of saw. Computer terminal and keyboard positioned on steel frame above cutting position. Wooden out-feed bench on steel frame to right of saw. Equipment mounted on reinforced concrete floor.

Dimensions: Available upon request

Options

- 8 dot ink jet - label components, e.g. TS3600/W6.

- Right hand or left hand feed input.

- Saw dust extractor.

- Spare blade.